The Complete Air Compressor Auditing Guide

Let's face it, energy isn't cheap and finding ways to cut energy costs is critical to the bottom-line.

In our last article, we showed you ways to improve your air system's performance and maximize efficiencies to save money.

Now, we will show you where you can save money by auditing your compressed air operations. This article takes a step-by-step approach on how to conduct an audit, what to look for, and how to implement the changes needed.

Why Conduct an Audit?

Research has shown1 that over 75% of compressed air costs come from the electricity used to power your compressor over its lifetime. Whenever a compressor is working longer or harder than it needs to, it's wasting energy and not working efficiently. In today's economy, eliminating every pressure drop, leak, and outdated piece of technology is critical for cutting bottom-line costs, which can mean millions of dollars for large-scale production facilities.

The most important thing to remember is that all parts of your air compressor system work together. If one part fails to work efficiently, other parts work harder to make up the slack, meaning you're wasting energy dollars and shortening the life of both individual parts and the whole system.

The best way to understand how much your air system is costing your business is to conduct a thorough audit to determine how much energy and power your compressors are consuming daily, and discover where improvements can be made.

How Much Does Compressed Air Cost?

Compressed air accounts for over $5 billion per year in energy costs in the United States alone, and accounts for about 10% of all electricity consumption in North America. Compressed air is not cheap or the most efficient energy source, so ensuring you're only using your compressor for necessary jobs is critical.

How to Calculate Compressed Air Costs

To calculate your cost of compressed air, you'll need to first determine how many kilowatt hours (kWh) your compressor is using. To do this:

- Determine how many hours per day the compressor is used. Remember to only record the actual run time in hours, and to do this accurately, use a stopwatch to monitor and record the 'on' cycles. Repeat this for a work week for best results.

- Determine how much power (or wattage) the compressor is using while operating (this can be found on the compressor's nameplate). If it isn't listed, multiply Amps x Volts to determine the wattage rating.

- Determine the total kilowatt hours used. To do this, multiply the wattage rating with how many hours the compressor is used, and divide that by 1000.

3,000 watts x 4 hours per day /1000 = 12 kilowatt hours (kWh/day)

3,000 watts x 4 hours per day /1000 = 12 kilowatt hours (kWh/day)

Next, you'll need to calculate the cost per kWh to run your compressor for the day (which is 4 hours in our example). To do this, multiply your kWh from above with the rate charged by your utility company per kilowatt. If the company charges 14 cents per kWh, your calculation will look like this:

| |

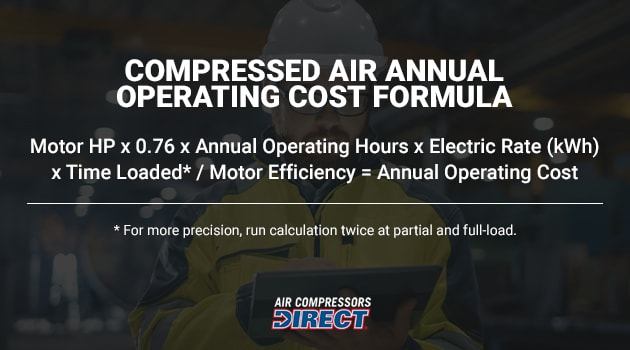

How to Calculate Cost Per Year

Now it's time to multiply the number above to determine how much you're spending on compressed air over a year. There are multiple ways to calculate this, however, we've listed the simplest formula2 below.

*Pro Tip: Most of the numbers needed below can be found on the nameplate of your compressor. You will also have to make this calculation twice; once for the cost of the compressor at full load, and once for the cost at partial load.

| |

Formula Key:

- HP—Total rated power of the motor. This number may be higher than what is listed on the nameplate, so also check equipment specifications).

- Service Factor—How far above rated horsepower that the compressor can work without damaging the motor. Can be found on nameplate.

- Total Operating Hours—Total hours the compressor is running per year. Take the number you found to determine kWh per day, multiplied by the number of days per year the compressor runs each year. Example: 4 hours per day, 6 days per week, 52 weeks per year (4 x 6 x 52) = 1,248 hours per year.

- Electric Rate—What the utility company charges per kilowatt hour (kWh) of energy ($ per kWh).

- Percent Time Loaded—Total amount of time compressor is operating.

- Percent Full Load—Percentage of full-load at the operating level.

- Motor efficiency—rating given at the operating level; can be found on nameplate.

This number is likely higher than you expected, but that's okay. It's never too late to audit your air system, implement changes, and reap the benefits of energy savings. However, we urge you to start looking at your compressor system today.

How to Conduct an Audit

For the most accurate audit results, we recommend getting a professional diagnosis—a diagnostic technician will use data-logging equipment to measure your load profile (the CFM and PSI you are using versus what you actually need to do the job).

For the most accurate audit results, we recommend getting a professional diagnosis—a diagnostic technician will use data-logging equipment to measure your load profile (the CFM and PSI you are using versus what you actually need to do the job).

From this data, you'll be able to see graphs that show exactly where you're wasting energy (and money). This data is critical to point to any irregularities or air-losses that are causing your air system to overwork and overcompensate.

An audit will consist of many measurements and factors3, and a walk-through assessment can be done in as little as 8 hours, or as long as a few days depending on the complexity and size of your system. The items listed below are recommended to be checked for a thorough analysis of your compressor system.

1. Eliminate Leaks & Pressure Drops

These are the culprits of most wasted energy costs, so make sure to identify and fix any leaks found in your air system's piping. Even a 1/8 inch diameter hole in a 100 PSI system can add up to over $1,200 in wasted energy over a year.4 Common places leaks can be found are:

- Aging Pipe—throughout the air lines, especially corroded joints

- Couplings—check the seals, they could be damaged from installation/use

- Drain Valves—look on receivers, filters, and all other equipment with valves

- Fittings—fittings may have come loose over time

- Flange Connectors—near where gaskets would need replacing

- Flexible Hoses—could have cuts or splits caused by abrasion

- Manifolds—Near closely placed connections

- Pneumatic Tool Ends—check for leaks in the connectors and seals

In addition to eliminating leaks, brainstorm ways to reduce pressure drops throughout your whole air system, especially those with long runs of air piping. One solution could be to reduce the diameter of your piping from 3" to 2", effectively decreasing pressure drops by increasing PSI. Another solution could be to shorten the distance (run) between your compressor and your air end.

2. Check Air Filters

Clogged filters increase energy costs by reducing flow rates and removing fewer particulates over time, forcing your compressor to work harder and pass damaging, poorly-filtered air through your whole system. If left unchecked, this can cause costly repairs down the line.

Clogged filters increase energy costs by reducing flow rates and removing fewer particulates over time, forcing your compressor to work harder and pass damaging, poorly-filtered air through your whole system. If left unchecked, this can cause costly repairs down the line.

We offer high-efficiency line filters to maximize savings at the air end. Regularly clean or replace all of your filters, and make sure you're using the right ones in the first place. Remember, dirty, unfiltered air will damage your compressor system, piping, and air tools.

3. Eliminate Artificial Demand

Manufacturers will use higher pressures (PSI) to over-compensate for pressure drops, leaks, and flow fluctuations to make sure that flow (CFM) demands can be met. This creates an artificial demand capacity that is often 25 percent higher or more than what is actually needed. This can throw off your calculated costs and force your compressor to work harder than it needs to—and wasting air in the process.

Operating at the lowest pressure possible will greatly reduce wasted energy, so instead of manually increasing pressure to fulfill the demand, consider a flow controller or pressure regulator to help increase the efficiency of the air you're already producing.

4. Consider a Pressure Regulator

Pressure regulators tightly control air pressure and keep your air-end tools running efficiently with minimal wasted air. Some regulators even have built-in filtration included for maximum protection. Consider using these at your air end location(s).

5. Assess Air Dryers & Heating Expenses

Compressing air quickly creates heat and condensation. Air dryers defend your pneumatic tools and machines longevity by cooling and removing the moisture in the air that would otherwise contaminate the air and damage the tank, lines, and other components of your compressor over time. Use the wrong type of air dryer and you'll waste a lot of money by overworking the dryer to fulfill a purpose it wasn't built for.

Compressing air quickly creates heat and condensation. Air dryers defend your pneumatic tools and machines longevity by cooling and removing the moisture in the air that would otherwise contaminate the air and damage the tank, lines, and other components of your compressor over time. Use the wrong type of air dryer and you'll waste a lot of money by overworking the dryer to fulfill a purpose it wasn't built for.

A refrigerated air dryer will work perfectly with scroll compressors or with a piston or rotary screw compressor that is designed with a built-in aftercooler. Otherwise, a regular refrigerated air dryer will work longer and twice as hard to cool high-temperature air—resulting in wasted energy, shorter dryer lifespan, and money out of the bottom line. There are high-temperature air dryers designed for this purpose and run efficiently at those heavy workloads.

Most of the electrical energy a compressor creates is converted to heat energy, which is often wasted. Smart applications (like a heat recovery unit) in your system may allow you to harness that energy to offset the costs of the compressor. Take space heating, for example. For large commercial buildings, it's possible to use the heat generated from your compressor to heat the building, or even to heat water for various hot-water applications.

6. Upgrade Your Storage Capacity

Imagine a storage reserve tank. It fills up the first time and isn't used unless it needs to be. The more storage you have, the less often your compressor will need to run, allowing you to do more work at fewer kilowatts per hour. Just remember, compressed air continues forming moisture the longer it remains compressed. As long as you'll use the extra air throughout a work day, more storage capacity can be a cost-friendly solution over time.

Imagine a storage reserve tank. It fills up the first time and isn't used unless it needs to be. The more storage you have, the less often your compressor will need to run, allowing you to do more work at fewer kilowatts per hour. Just remember, compressed air continues forming moisture the longer it remains compressed. As long as you'll use the extra air throughout a work day, more storage capacity can be a cost-friendly solution over time.

7. Turn the Compressor Off

It seems simple enough, but many manufacturers leave their compressors on when not in use, like over weekends or off-hours. This is simply unnecessary and wastes energy dollars. Turn off your compressor when outside operating hours and when not in use.

Develop a Preventative Maintenance Schedule

Unfortunately, maintenance costs are some of the first to get cut from tightening budgets, even though they should make up about 12% of the total cost through the life of your compressor. Though it's easy to ignore small problems, they inevitably result in larger, more costly consequences that could shut your production down for days at a time while repairs are made. Maintenance kits make it easy to manage the upkeep.

The best way to keep your energy costs manageable and ensure the long life of your compressed air system is to create an aggressive, ongoing maintenance schedule to make sure no parts of your system go untouched, and no problems go unnoticed.

- Educate your technicians and employees about the compressor's technical specifications. Show them how to detect leaks, what to look for, and incentivize them for best results.

- Inspect Consistently and plan on a specific time to check all parts of your air system, whether during production hours or in-between them. Tag and photograph your findings.

- Follow up and make sure the repairs have been made after being tagged.

Benefits of Preventative Maintenance:

- Catch new leaks/pressure drops/other issues before/as they happen

- Replacing filters as they are recommended keeps efficiency high and air clean

- Trained employees who can properly use and maintain your system

- Prevents costly downtime due to major repairs

Next Steps

Take control of your system and make sure it's saving you the most money possible despite increasing global energy costs. Implementing the changes in this article is a sure way to improve your current air compressor system or return it to its former glory.

![]() NEXT: Rotary Screw Compressor Buyer's Guide

NEXT: Rotary Screw Compressor Buyer's Guide

Commercial Efficiency Navigation:

Main Guide | Commercial Buyer's Guide | Reduce Energy Costs | How to Audit Your System | VSD Technology | Air Treatment Systems