Duty Cycles Explained

Look up 'duty cycle' and you're likely to find a ton of complicated information, but it's actually a simple concept. And understanding what a duty cycle is can be the difference between getting the job done right or being left frustrated.

In this article, we cover everything you need to know about what duty cycles are and how they relate to air compressors.

What's a Duty Cycle?

Imagine you are blowing up a balloon. You breathe in to fill up your lungs and breathe out, pushing air into the balloon. That's a 100% cycle of air coming in and going out.

Now, imagine you fill a tank with your lungs, and it only takes half the tank's air to fill the balloon before you need to replenish the air. That would be a 50% cycle. Easy, right?

The capacity of your lungs and the speed in which you breathe is what we consider CFM, cubic feet per minute. The strength needed to blow up the balloon, we call PSI, or pressure per square inch. The smaller the balloon, the less air or CFM is required. The harder it is to blow it up, the more pressure or PSI it requires.

Air Compressor Duty Cycles

More technically, an air compressor's duty cycle refers to how long it takes its pump (driven by a motor) to fill up its tank. If the compressor does not have a tank (like your lungs), it will always have a 100% duty cycle. If the compressor has a tank, it just means that one full cycle is the total time it takes to fill the tank, or when the compressor runs, stops, and runs again. This 'on-off-on,' or duty cycle is sometimes referred to as run-time vs rest time.

For example, if an air compressor's total cycle time was 10 minutes, and it ran for 6 minutes during that time, you could say it has a 60% duty cycle, which means 4 out of 10 minutes the compressor was resting/cooling down during a cycle.

Additionally, the 'duty cycle' is the amount of time a compressor is providing consistent pressure (PSI) and flow (CFM).

So, if a compressor advertises a 100% duty cycle at 25 CFM and 125 PSI, it means that the compressor will provide 25 CFM and 125 PSI for 100% of the time with the help of a storage tank. In this example, the same compressor could also provide higher power, say 150 PSI and 10 CFM at 50% duty cycle, and could be advertised that way as well. In these examples, the duty cycle refers to consistent flow and pressure for a specified percentage of the total cycle time.

Duty Cycle Standards

The duty cycle is generally accepted as a guideline to help people understand how often a compressor cycles on and off while working. However, keep in mind that there is no standard definition all manufacturers use to describe their compressor's duty cycle. Because of this, some manufacturers may not list duty cycle ratings.

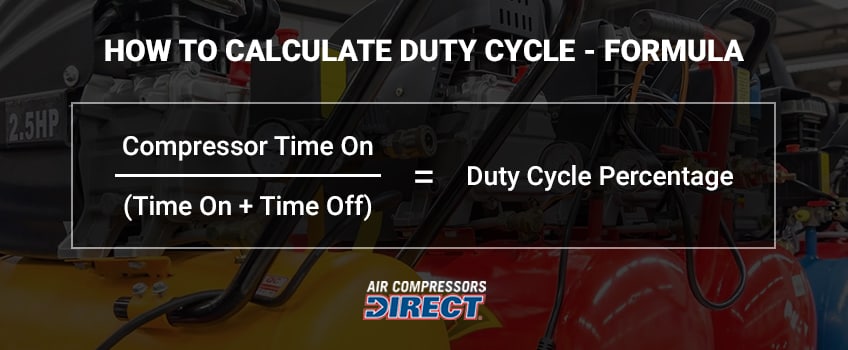

How to Calculate Duty Cycle Formula

In general, the duty cycle formula often used for calculation is expressed as Compressor time on / (time on + time off) = Duty Cycle percentage.

For another example, say a compressor has a 2-minute total cycle time and runs for 1 minute during the cycle. Using this duty cycle formula, we have 1 minute / 2 minutes = 0.5, or 50% duty cycle. In this case, this means the compressor will deliver pressurized air for 60 seconds, then you will need to wait 60 seconds to get more pressurized air to use again. This is why it is an important measuring tool for sizing an air compressor.

Why Does Duty Cycle Matter?

The duty cycle is very important when it comes to understanding how a reciprocating air compressor functions by cycling on and off. The ratio between the run time and the rest time is the duty cycle rating, which helps you understand how the compressor will operate and if it will fulfill your air needs when sizing a compressed air system.

In other words, a duty cycle rating indicates how long a compressor should be working and how long it should be resting between cycles, and it’s your responsibility not to overwork your compressor.

100% Duty Cycle vs Continuous Run

A 100% duty cycle simply means the compressor will deliver a consistent CFM and PSI the entire time it is in use, which is different from it being able to run continuously. Even if a piston-type compressor is rated at 100% duty cycle, it eventually needs to stop and cool down. This is an essential operation for compressors that are not rated as continuous runs and will prevent premature damage to the compressor.

Continuous-run compressors are rated to run continuously and only idle down when the compressor is not being used. Normally, these types of compressors are reserved for industrial applications. Most commonly, rotary-screw compressors are used in continuous duty applications.

Prevent Over-Cycling

Sizing your compressed air system properly is extremely important to prevent over-cycling or shortening the life span of your system. Make sure the compressor you choose meets your PSI and CFM requirements at a duty cycle that is acceptable for your business.

How Properly Sizing a Compressor Saves Money

Duty cycle ratings are an expression of how efficiently the air compressor will work for you and are a great indicator of how it will run in your applications. If you are sizing a new system, replacing a compressor, or want to find other ways to save money, read our guide on how to Reduce Energy Costs and Increase Efficiency.

Direct Current (DC) Compressors

DC compressors are powerful, efficient, and perfect for off-roading. They run on 12-volt or 24-volt power and are installed directly on a vehicle, with a tank or without one. DC compressors without a tank are considered 100% duty cycle compressors because they don’t store air at all, just continually compress and deliver air as long as they are being used. Compressors that fit this class are referred to as continuous-duty air compressors.

DC compressors are powerful, efficient, and perfect for off-roading. They run on 12-volt or 24-volt power and are installed directly on a vehicle, with a tank or without one. DC compressors without a tank are considered 100% duty cycle compressors because they don’t store air at all, just continually compress and deliver air as long as they are being used. Compressors that fit this class are referred to as continuous-duty air compressors.

However, not all DC compressors are built the same! There are vast differences in quality. For instance, some are truly military-grade products, and others are designed as glorified inflators. Not all DC compressors without a tank are going to be considered a 100% duty cycle either. For example, a DC compressor could be rated at a 15% duty cycle at 100 psi. Lastly, there are other various uses for DC compressors, however, off-roading is the most popular usage.

Rotary Screw Air Compressors

If you need an industrial air compressor that delivers consistent power at continuous duty, you’ll want to choose a rotary screw air compressor. Not only does it work better for fixed-speed applications, but a rotary screw compressor also saves money in the long run, especially when utilizing variable-speed drive (VSD) technology, which maximizes power and duty cycle efficiency so nothing is wasted while the compressor is working.

If you need an industrial air compressor that delivers consistent power at continuous duty, you’ll want to choose a rotary screw air compressor. Not only does it work better for fixed-speed applications, but a rotary screw compressor also saves money in the long run, especially when utilizing variable-speed drive (VSD) technology, which maximizes power and duty cycle efficiency so nothing is wasted while the compressor is working.

Last Thoughts

Duty cycles are important for many reasons when it comes to air compressors, and hopefully, you now have a better idea of what to look for when looking at the specs. Just remember that the duty cycle is not a standard rating and, like decibel ratings, may or not be available for a type of compressor. If it is available, it is a great metric to use, but also take that rating with a grain of salt.